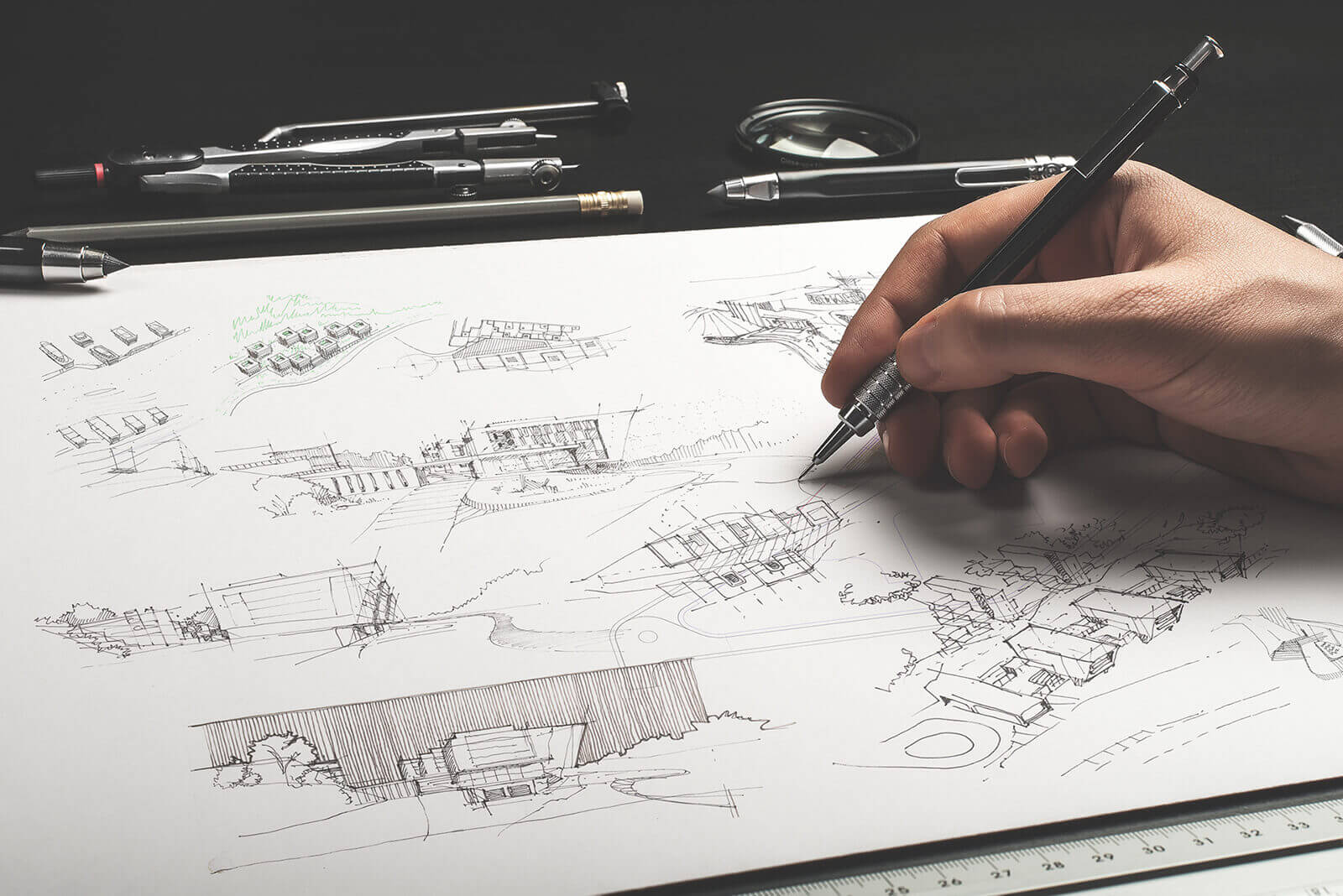

Given our extensive experience in the industry, we propose the client an ideal solution, in line with their wishes and needs. The design solution, how the building will look after construction and custom furniture production, is presented through unique 2D, 3D models, and VR glasses, depending on the type of project. The client gets the opportunity to see how the building will look upon completion of the job. If the client approves the project, the conceptual solution is sent for technical elaboration.

Our team of architects carefully analyzes every aspect of the conceptual project during the technical elaboration, paying attention to the smallest details to achieve outstanding aesthetic and functional results. After completing the technical elaboration and creating technical drawings, these drawings are forwarded to production for the manufacturing of furniture and interior elements according to the project. We would like to emphasize that the possibility of making mistakes is minimized since our input-output information between technical preparation and production is digitized.

Our production spans over 8000m². It consists of state-of-the-art machinery and equipment for furniture manufacturing. The interior production process is fully digitized. Each operator uses a tablet at their workstation, enabling digital monitoring of the entire production process. Every element of each piece of furniture has its own barcode. Each piece of furniture goes through the production process via a barcode reading mechanism. Every function has its barcode reader. Semi-finished products are packed and transported from the production warehouse to the final destination for assembly.

We deliver the manufactured furniture and interior furnishing elements to the project address and assemble them on-site. Communication with architects, production, and the project manager, along with decades of experience in teamwork, enables us to mount all elements and carry out their installation in the quickest and most efficient manner possible.

We are beyond impressed with the level of care and professionalism displayed by the Active Design team throughout the entire process. Their commitment to excellence has undoubtedly contributed to the overall success and outstanding quality of our hotel.